How To Solve The Tension Problem Of The Slitter?

2019-11-20 15:04 ┬Ā┬Āadmin

The structural advantages of the slitting machine are mainly reflected in the fact that the middle part of the slitting machine has a spindle for processing the paper tube, and the front end of the spindle is fixed on the base by a set of bearings, and a pulley is arranged at the center of the set of bearings; The device has a compression cylinder, and the upper end of the support rod of the cylinder has a set of support rod bearings to support the main shaft. At the upper end of the slitting machine, there is a main cutter shaft, and a plurality of blades are arranged thereon, and arranged according to a certain gap; a support frame of the main cutter shaft which is further disposed at the top of the slitter-winder, at the center of the support frame There are supporting cylinders. After the cutting, the operation is restarted; when the set length is reached, the cutting signal is sent without stopping, and the slitting machine dynamically cuts the machining during the material movement.

When the slitter will have tension problems when it is used, how should it be solved? The manufacturer of High Speed Stainless Steel Slitting Mill will come to tell you.

For the tension control of the slitter, the key issue is that, in addition to the steady state, its time-line speed is constant, and for its system, it is also required to be in constant tension unwinding. The state, as well as the variable tension winding state. That is to say, in the process of winding up, its winding tension is adjusted accordingly as our winding radius increases.

Above we talk about the tension control of the slitter, it is the tension taper control. Its main function is to prevent the internal stress of our coil from increasing, and then the strip near the core can be squeezed, and then deformed and wrinkled. Waste will be produced, which will cause the edges of the strips between our adjacent discs to overlap each other, resulting in the inability to separate the discs.

In addition, for the operation of the slitter, such as the Narrow Width Coil Slitting Line, we should note that whether it is unwinding or winding, its winding diameter will follow in the operation of our slitting machine. A wide range of changes in time to cause a wide range of changes in a parameter within the control system corresponding thereto. In this case, it is a final result for directly affecting the dynamic and static quality of the system.

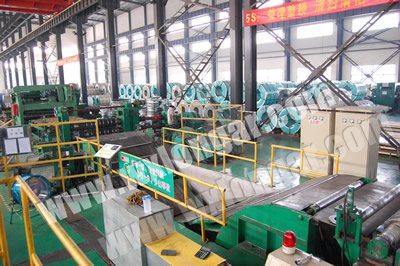

Metal Steel Coil slitting Machine

For this, we must know that the system of its slitter is good or bad, the main thing is to see if our system can meet its requirements of a process. Be careful to use a more advanced design idea to control, as far as the system itself is concerned, to ensure a good mechanical and electrical performance.

As far as the status quo of the development of the slitter is concerned, the manufacturing industry of our slitter is also inconsistent. Many companies, if they produce the technology, use the technology that has been used abroad for decades. . In this respect, in fact, for the level of automation of the machine, there is still a lot of room for improvement.

The above is the method for the Metal Steel Coil slitting Machine Exporter to share the problem of solving the tension of the slitter, I hope to help everyone.

┬® 1994-2020 Wuxi Longar Machinery Manufacturer Co.,Ltd.

┬ĀAll Rights Reserved ┬Ā ┬ĀDesign by WxlonGar┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬ĀPrivacy Policy

Russian

Russian ń«ĆõĮōõĖŁµ¢ć

ń«ĆõĮōõĖŁµ¢ć