Precautions For Use Of Slitter Round Blade

2019-11-09 09:19 ┬Ā┬Āadmin

I don't know if everyone knows the slitting machine, have you understood it deeply? For the use of this machine, blades are essential. The following Slitting Blade Manufacturer will introduce some precautions about the circular blade of the slitting machine and the factors that will affect the wear intensity.

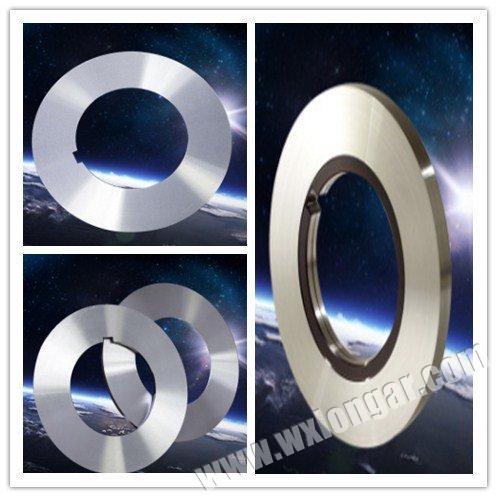

Slitter Blade

The first thing to notice is how to install the Slitter Blade:

1. First wipe off the rust-proof oil on the cutting circular blade. Place the cleaned blade flat on the table, place it on the lower knife, and open the upper knife upward.

2. The keyway is placed on the thimble of the lower knife, and the initial part is completed by overlapping. Then use the gasket of the cutting knife to fix and fix the upper knife. You can use some tools to prevent your hands from being hurt by the sharp edge if you use a strong sleeve directly.

3. The last step is to talk about the clamping spring being clamped between the upper and lower slitting cutters, so that the upper and lower blades of the butterfly-shaped circular blade are installed.

4. The butterfly-shaped slitting circular blade is a very easy-to-use knife for slitting tape. The most commonly used materials are front steel and die steel. After selecting the materials, use the correct installation method to install the upper and lower blades. Used smoothly in the production process!

In addition to the use of slitter circular blade:

1. When not using a circular blade, hang the blade vertically on a dry rack. Do not lay the circular blade flat. Placing it flat will cause deformation of the circular blade.

2. The serrations of the circular blade are hard and sharp, and they cannot collide or fall to the ground.

3. Protective cover, work gloves, hard hat, safety shoes, and protective glasses are required when operating.

4. Before installing the circular blade, it is necessary to confirm the performance and use of the saw table to ensure that the cutting direction indicated by the arrow of the circular blade is the same as the rotation direction of the saw table. Do not install it in the opposite direction. Inserting it in the wrong direction may cause the blade saw teeth to fall off, preventing accidents.

5. When installing the circular blade, it is necessary to check whether the circular blade is cracked, distorted, flattened, or lost teeth before installing.

6. After the installation is complete, make sure that the center hole of the circular blade is firmly fixed on the flange of the saw table. If there is a washer, cover the washer, and then gently push to confirm whether the circular blade rotates eccentrically .

7. When in use, do not exceed the specified higher speed.

8. After the new blade is pre-converted before use, it needs to be pre-rotated for one minute before use, so that the cutting table can be cut only when it is in working condition.

9. The hardness requirements of round blades are more important. Sometimes your material is better. If the hardness requirements are not reasonable, the blades will collapse and soft.

Finally, we must pay attention to the factors affecting the wear of the circular blade of the slitter:

1. Production materials

The material of round blade is hard and wear-resistant, but the lower the toughness. Hardness and toughness are opposite, which is also an aspect that needs improvement. If it is a graphite round blade, the material can be selected to have better toughness.

2. Diamond-coated round blades have the advantages of high hardness, good abrasion resistance and low coefficient of friction, etc., which is the most ideal manufacturing method at present. However, the production cost is high, and the domestic technology in this area is not mature enough. Graphite-coated round blades are widely used and highly practical.

Therefore, you should pay attention to the above issues when using the Slitter Cutter blade. Hope to help everyone.

┬® 1994-2020 Wuxi Longar Machinery Manufacturer Co.,Ltd.

┬ĀAll Rights Reserved ┬Ā ┬ĀDesign by WxlonGar┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬Ā┬ĀPrivacy Policy

Russian

Russian ń«ĆõĮōõĖŁµ¢ć

ń«ĆõĮōõĖŁµ¢ć